# 1

Basic property

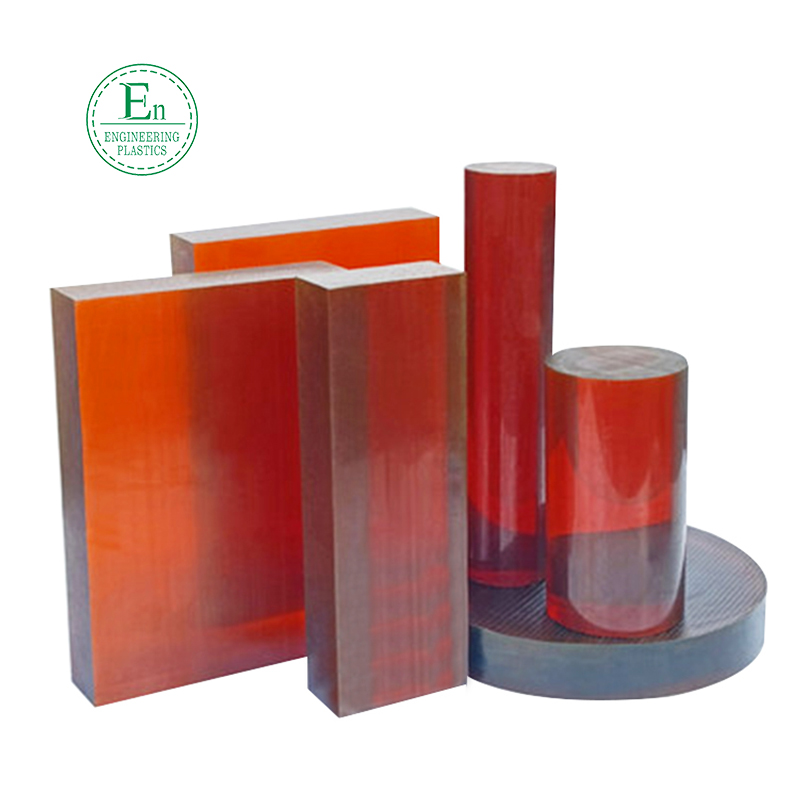

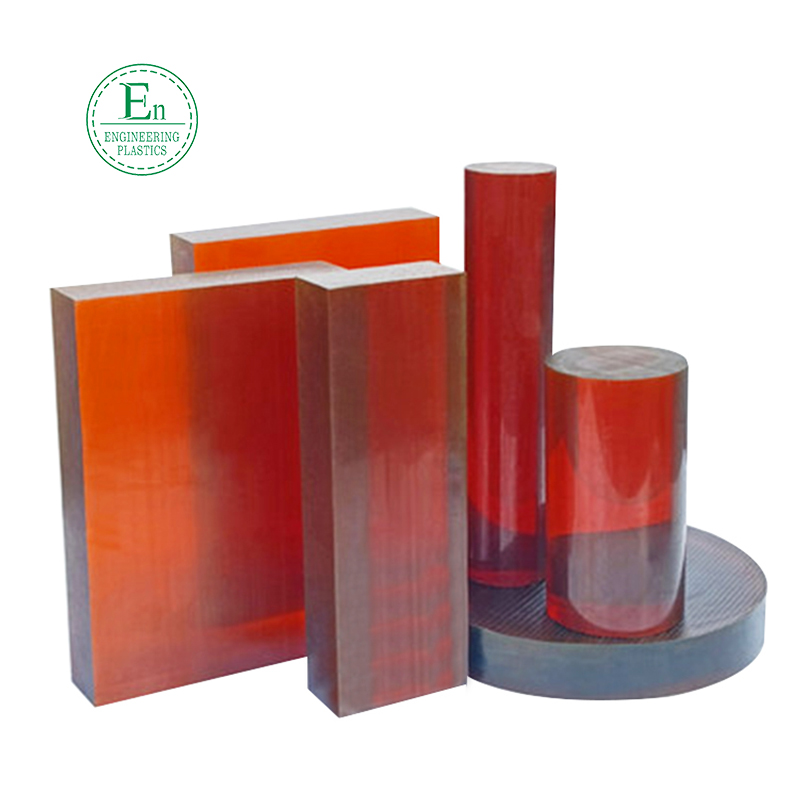

PPSU is a linear polymer with a slight amber color. In addition to strong polar solvents, concentrated nitric acid and sulfuric acid, it is stable to general acids, bases, salts, alcohols, aliphatic hydrocarbons, etc. Partially soluble in ester ketone aromatics, soluble in halocarbon. Good rigidity and toughness, high temperature resistance, heat oxidation resistance, excellent creep resistance, corrosion resistance to inorganic acid, alkali, salt solution, ion radiation resistance, non-toxic, insulation and self-extinguishing good, easy molding processing.

The performance parameters of the PPSU are as follows:

The thermal deformation temperature is 207℃, the relative density is 1.29, the tensile strength is 94 MPa, the elongation at break is 60%~120%, the compressive strength is 150 MPa, the bending strength is 127 MPa, the notch impact strength is 690 kJ/m2, the hardness (Rockwell) is 110, and the bending elastic modulus is 2.6 GPa (23℃). The tensile modulus of elasticity is 2.4GPa (23℃), the thermal deformation temperature is 207℃(1.86MPa), and the maximum temperature of continuous use is 180℃.

Resistivity 3.2×1015 Ω·cm (23℃)

# 2

Preparation method

The basic resin composition prepared by the reaction of

Polyphenylene Sulfide with peracetic acid.

# 3

use

Suitable for the production of heat-resistant parts, insulation parts, wear resistant parts, instrument parts and medical equipment parts, polyarylsulfone suitable for the production of low-temperature working parts.

Polysulfone is commonly used in the electronic and electrical industry to manufacture integrated circuit boards, coil tube frames, contactors, sleeves, capacitive films, high-performance alkaline battery shells.

Polysulfone is used in household appliances for microwave oven equipment, coffee heaters, humidifiers, hair dryers, cloth dryers, beverage and food dispensers, diet tableware, water cups, baby bottles, etc. It can also replace non-ferrous metals for precision structural parts such as clocks, copiers, cameras, etc.

Polysulfone has passed the relevant specifications in the field of medicine and food in the United States, and can replace stainless steel products. Because polysulfone is resistant to steam, hydrolysis, non-toxic, high temperature vapor disinfection, high transparency, good dimensional stability, it can be used as surgical tool tray, sprayer, fluid controller, heart valve, pacemaker, gas mask, dental base and so on.

Because PPSU is A safe material, it does not contain endocrine disrupting carcinogenic chemicals (environmental hormone: bisphenol A), and as a material with excellent heat resistance, heat resistance temperature up to 207℃. Therefore, it can be repeatedly boiled at high temperature and sterilized by steam. It has excellent resistance and acid and alkali resistance, can withstand general potions and cleaning agents, and will not produce chemical changes. Lightweight and drop resistant, it is the best in terms of safety, temperature, hydrolysis and impact resistance. But the price is relatively expensive.

# 4

Properties and applications of PPSU modified by filler

The addition of fillers can significantly improve the wear properties of PPSU, glass fiber reinforced PPSU can be used with lubricants in some cases, in order to meet particularly important wear needs, by adding carbon fiber, graphite and

PTFE, these materials have surprisingly satisfactory tribological properties when exposed to high temperatures and different media. The performance of components made from PPSU, in addition to the actual thermal properties of the particular product, depends on the length and type of high temperature effect, the mechanical load, and the design of the component. PPSU is a plastic with high strength, high toughness and high energy absorption capacity, due to its amorphous structure, these characteristics are maintained in a wide range, even under the conditions of 140~180 ° C, compared with other unreinforced polymers, these modified PPSU materials can still withstand quite high stress, PPSU absorbs moisture in the air, PPSU absorbs moisture in the air. Compared with dry, newly made injection molds, water absorption causes only a change in size, and the impact strength of the edge is increased, the tensile strength and tensile elastic modulus are only slightly affected, and the creep behavior is significantly improved relative to room temperature due to PPSU's glass transition temperature of 225 ° C. As a structural material, PPSU not only has excellent thermal stability, but also has many other characteristics, making it an important material widely used in the automotive and transportation industry, this high-performance material has a unique temperature distribution curve, PPSU short-term tolerance temperature up to 220℃, long-term use up to 180℃, can withstand 170~180℃ oil temperature environment, Good dimensional stability, PPSU has the ability to heat water and refrigerant, fuel resistance, fluorine resistance and other excellent comprehensive characteristics, with these outstanding characteristics, PPSU can be used to produce high-quality technology and high load bearing products, but also become the preferred material to replace metals, ceramics and hard polymers.

Typical PPSU application advantages such as design suitability, low quality components, crack resistance, reusability and cost savings from reuse have led to PPSU being increasingly used in hot food preparation and reheating. Especially suitable for high-pressure parts, high-pressure parts must show high dimensional stability and good mechanical properties in the temperature range of -50~160 ° C, good electrical insulation, high heat aging, excellent fire resistance, and good chemical corrosion resistance and hydrolysis resistance. The modified PPSU has excellent heat aging or thermal stability in the air, and the relative temperature index measured by UL746B is 155~190℃, which is defined as the storage temperature, at which the tensile strength is reduced to 50% of the initial value after 20000 h, and in many cases this temperature can be considered as the long-term use temperature. If exposed to impact loads, the relative temperature index is reduced by about 10 ° C, components made of PPSU can be repeatedly sterilized with superheated steam, and largely maintain their transparency and their high level of mechanical properties, because its toughness and elongation at break change very little after multiple sterilization treatments, in order to offset the splitting stress. The residual stress level in manufactured products should be kept as low as possible during manufacturing, PPSU should use products with high viscosity as much as possible in the sterilization cycle, and should avoid mechanical stress during sterilization, so that sterilization cycles may be as many as 100, making it possible to perform even 2000 superheated steam sterilization damage without forming any rupture under load. As an amorphous thermoplastic material, PPSU polymer is transparent, which makes it suitable for functional optical applications such as electronic camera lenses, PPSU produced by a company in the United States is used in electrical engineering and electronics applications, PPSU has a very ideal combination of properties, good electrical insulation (high volume resistivity and surface resistivity), high breakdown rating, high electrical conductivity, and high electrical conductivity. Ideal dielectric value, outstanding mechanical properties even at high temperatures, high long-term use temperature, and very good fire resistance, PPSU's creep resistance like most aromas, electrical properties are only slightly affected by the absorption of moisture, and its dielectric constant is basically stable over a wide range of frequencies and temperatures from -50 ° C to the glass transition temperature. The dielectric loss factor shows that only the edge depends on the frequency and temperature, and the dielectric loss factor of polar plastics is very low. PPSU begins to degrade when it is higher than 400℃, and the degree to which flammable gases reach the combustible concentration depends on the heating and ventilation conditions. The main substances formed in the early PPSU combustion process are carbon dioxide, water and sulfur dioxide. If oxygen is insufficient, carbon monoxide may be produced.