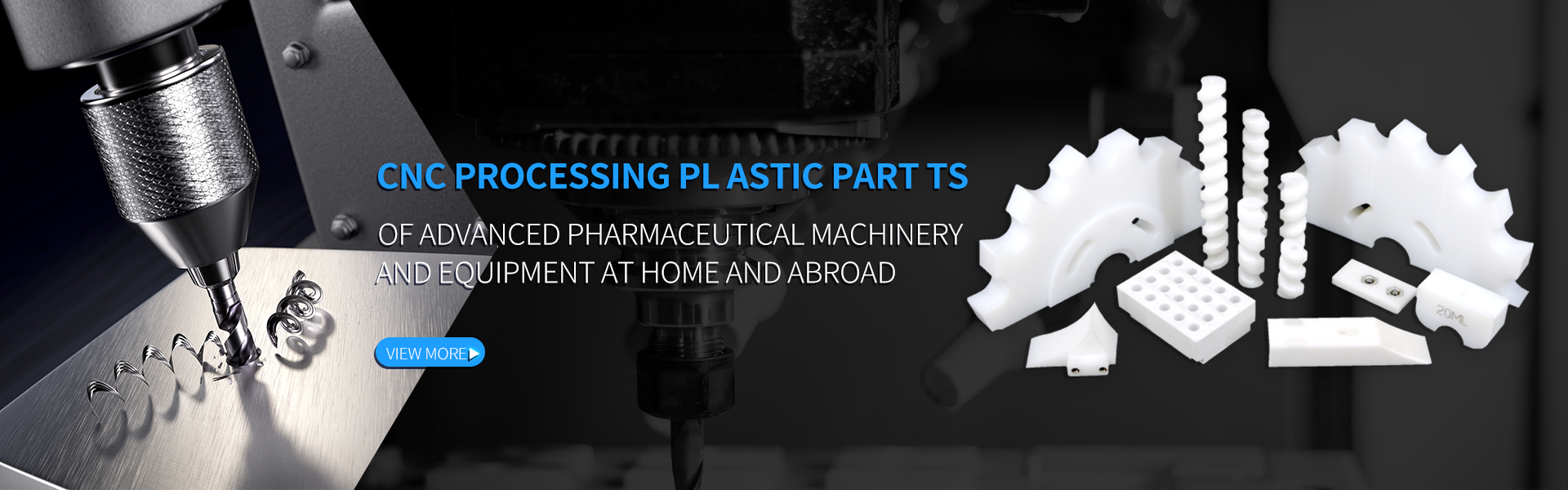

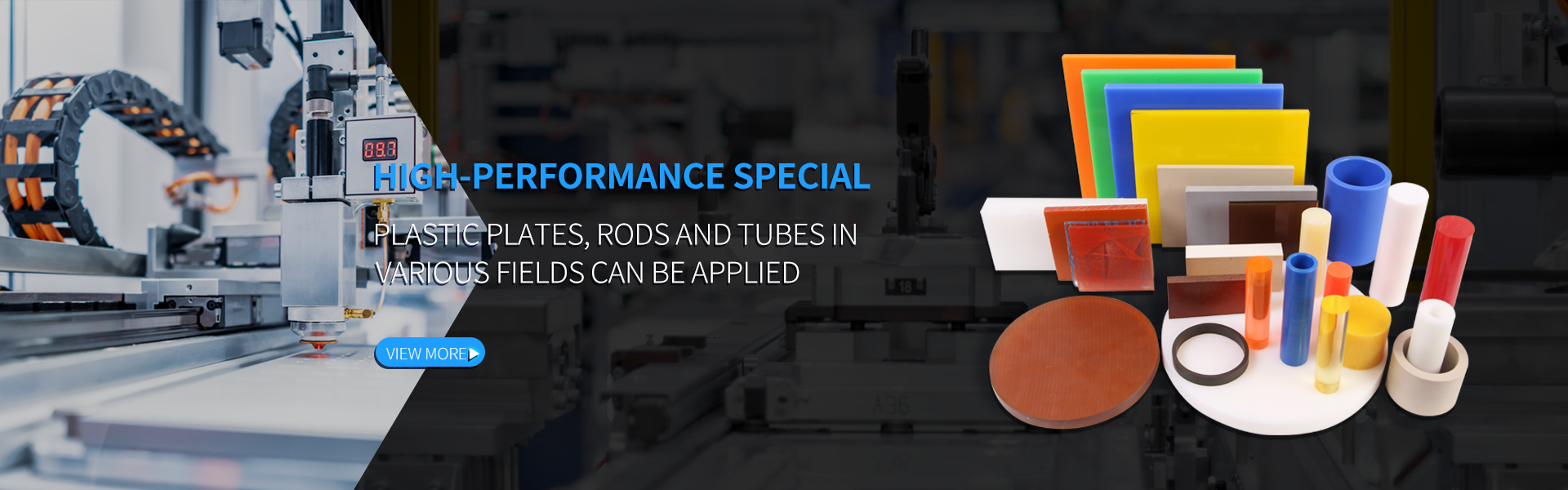

Guangdong Engineering Plastics Industries (Group) Co., Ltd., located in Huangpu District, Guangzhou, China. Workshop with 10000 m² floor space. Our company has the experiences in manufacturing engineering plastic industry for more than 15 years. Guangzhou Engineering plastics company has full set of high efficiency producing equipment and advanced numerical control machinery, such as: High-precision CNC molding manufacture machines, High-accuracy EDM machines, High-precision mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines, Double color injection machines, fine carving machines, Horizontal lathes, milling machines, etc. Our company has many senior engineers with 15-25 years experience! Rich experiences and technology for manufacture, with design, research and development ability, support personalized customization. we can customize all kinds of Engineering plastics products according to customers’ drawings or samples, such as: General engineering material: Nylon sheet, Nylon gear and rack, Nylon guide, Nylon pulley, P O M sheet, P O M gear and rack, P O M chain, P O M bushing, U H M W-P E sheet, U H M W-P E guide rail, P T F E Sealing ring, ect. High performance material: P E E K sheet, P E E K rod, P E E K Tube, P P S sheet, P P S rod, P E I sheet, PPSU sheet, PI sheet, PBI sheet and many machined parts. Moulding accuracy can reach micron level (0.001mm). Products Tolerance +/-0.01mm. We customized many products for many famous domestic customers and overseas customers, Also Export to USA, UK, Canada, Germany, Italy, France, Mid-East, Australia, New Zealand, Singapore and so on. We have gotten the good reputation in the World.